Automatic Laser Production Line Scheme For Pouch Battery

1、With MES data acquisition and processing, tracing, processing functions, on-line control of product quality.

2、Realize automatic production, reduce manual operation, the whole line production efficiency.

3、Can be customized according to customer needs of automatic production line program.

4、Can be customized according to the specific needs of customers.

Product Features

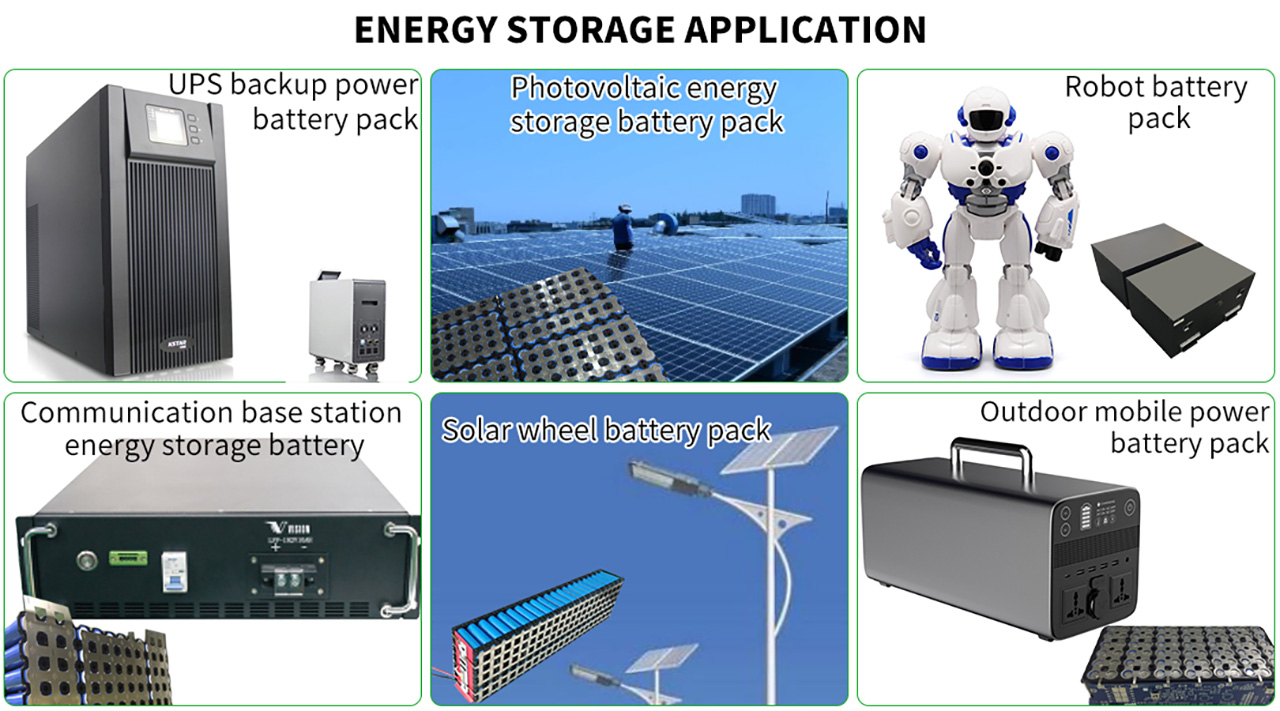

Application Areas

The product is suitable for welding 18650 26650 21700 32650 energy storage power supply field: UPS power supply, outdoor mobile power supply, mobile power supply; Garden tools: lawn mower, chainsaw, medicine sprayer; Home power tools: sweeper, vacuum cleaner, electric drill, robot; Digital power tools: mobile phone charger, drone; Travel power tools: 2-3 - wheel electric car, elderly mobility cart, golf cart; Street lamp battery pack, solar street lamp, balance car battery pack, locomotive battery pack, start battery pack module and other fields. Automatic compensation welding needle, water cooling heat dissipation welding head, very beautiful welding effect, eliminate fake welding, since the current welding detection, high-end quality, durable, one-year warranty, lifelong maintenance!

FIVE REASONS TO CHOOSE US

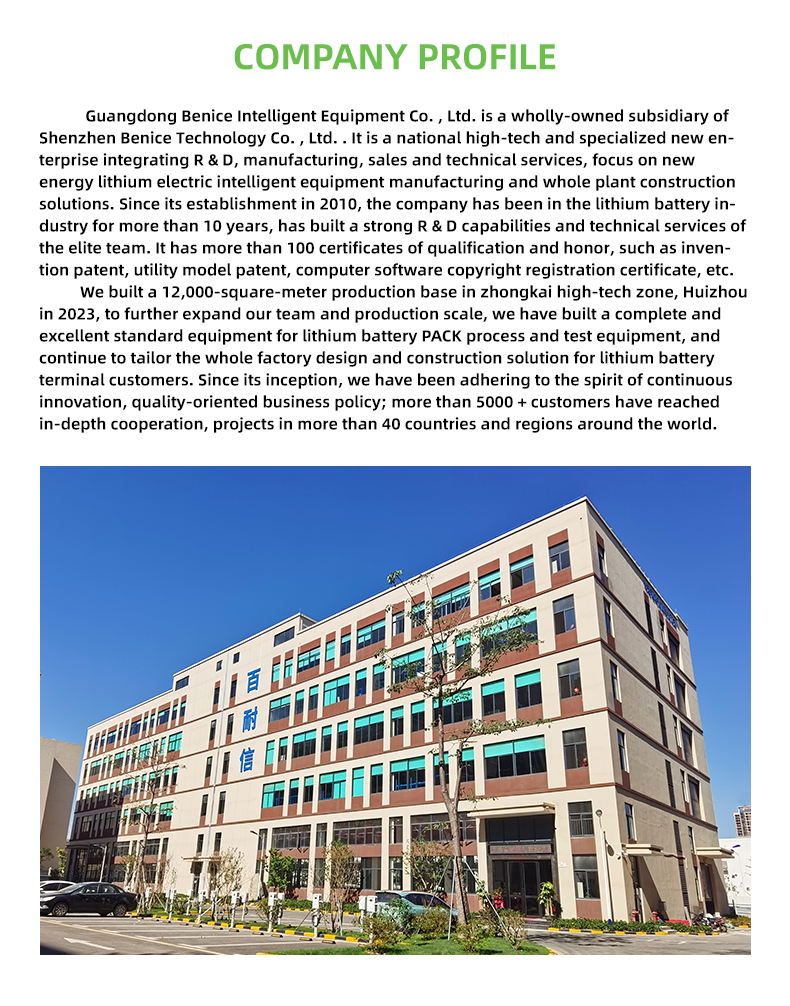

1、Benice is a provider of solutions for the manufacturing of new energy lithium battery intelligent equipment and overall factory construction.

2、The founder, who was born as an electronic engineer, has been deeply involved in the lithium battery industry for more than 16 years. He leads the entire R&D team and continues to

3、The products cover the equipment required for all processes of lithium battery PACK, and provide customers with various standardized products for production and

4、Both sheet metal and machining are independently developed and produced, ensuring efficient production while strictly controlling quality and fast delivery.

5、Tailor-made automation equipment for many lithium battery PACK factories and lithium battery application terminals, and provide overall production line design and manufacturing services.